Durable Eco-Friendly Style–biodegradable poly bags Supply

Biodegradable poly retail bags are produced with eco compostable materials for packaging needs. Our wholesale company offers durable, sustainable solutions.

Eco-Friendly Materials:Made from compostable PLA, PBAT, or corn-starch blends, reducing plastic waste and environmental impact.

Durable & Tear-Resistant:Strong structure ensures reliable performance for retail packaging, shipping, and daily handling.

Lightweight & Flexible:Easy to store and use, offering smooth packing and improved customer experience for retail businesses.

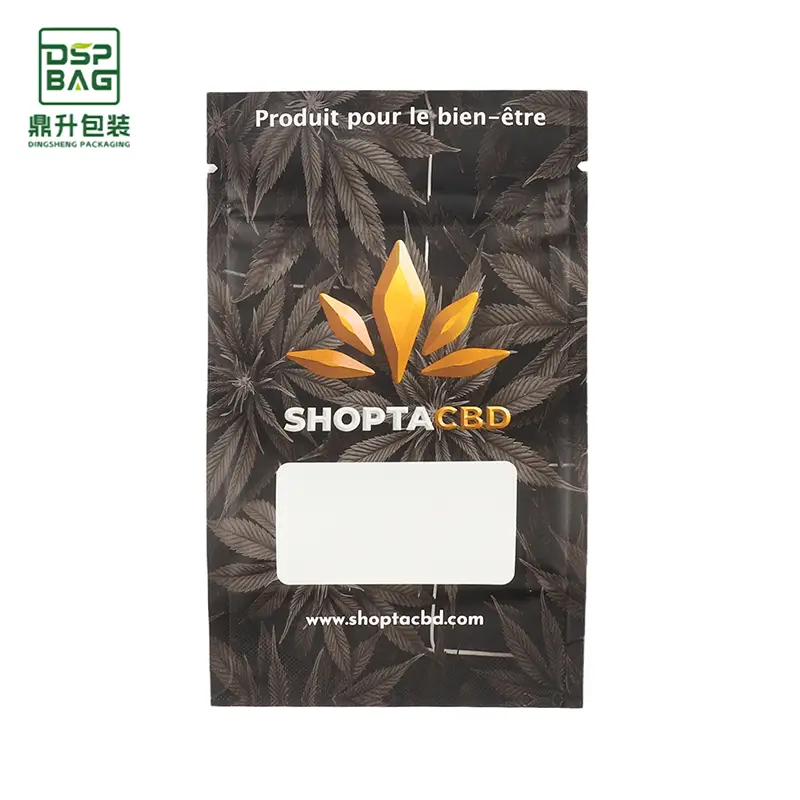

Customizable Options:Supports various sizes, thicknesses, printing, and branding to match different retail or commercial needs.

Ideal for B2B Supply:Suitable for bulk orders, wholesale distributors, and retailers seeking sustainable packaging solutions.

biodegradable poly bags Description

Durable Eco-Friendly Style – biodegradable poly bags Supply offers compostable, plant-based packaging designed for retail and commercial needs. Our biodegradable poly retail bags provide strong load-bearing performance, multiple size options, and clean branding surfaces for custom printing. As a professional wholesale supplier and manufacturer, we support bulk orders for stores, distributors, and eco-focused brands. These biodegradable poly bags help customers reduce plastic waste while improving packaging efficiency and sustainability across retail operations.

biodegradable poly bags+ Technical/Data Sheet

| Item | Specification |

| Product Name | Biodegradable Poly Bags |

| Material | PLA / PBAT / Corn Starch |

| Color | Transparent / Green / Custom |

| Bag Type | Flat Bag / Zipper Bag / Retail Bag |

| Thickness | 0.02–0.08 |

| Width | 100–600 |

| Length | 150–800 |

| Capacity | 0.5–10 |

| Load Bearing | 1–8 |

| Tensile Strength | ≥18 |

| Biodegradation Rate | 100% |

| Temperature Resistance | -20 to 60 |

| Printing Options | 1–8 Colors |

| Packaging | Cartons / Poly Bundle |

| Certifications | EN13432, ASTM D6400, OK Compost |

| Applications | Retail Packaging, Shopping, Gift Packing, E-commerce |

| Supplier Type | Manufacturer / Wholesale / Exporter |

These bags are typically made from polymer resins mixed with special additives (such as oxo-accelerants or biodegrading agents). These additives accelerate the bag’s fragmentation and subsequent decomposition in specific environments (e.g., light, oxygen, or microbial action). They break down into small pieces first, which are then further consumed by microbes.

This is a key distinction. Compostable means the bag will fully decompose into $\text{CO}_2$, water, and biomass within a specific timeframe (e.g., 90 days) in a commercial composting facility, leaving no toxic residue (often certified by standards like ASTM D6400 or EN 13432). Biodegradable simply means the material will eventually be broken down by biological processes, but the time, environment required, and resulting residue are generally not strictly standardized.

Modern biodegradable poly bags are designed with durability in mind. Their load-bearing capacity and tear resistance can typically meet or closely approach the standards of traditional low-density polyethylene (LDPE) or high-density polyethylene (HDPE) bags, making them suitable for everyday retail, mailing, or waste disposal needs.

Under normal dry, dark, and cool storage conditions, the shelf life of these bags is usually between 6 and 12 months or longer. They are not expected to start degrading “on their own” while unused. The degradation process usually requires exposure to trigger factors (like heat, moisture, sunlight, or microbial activity) to accelerate.

Yes. Most suppliers support custom printing on these eco-friendly bags, including brand logos, recycling instructions, and custom designs. The inks used are usually required to be water-based, non-toxic, or eco-friendly inks to ensure consistency with the product’s overall environmental claim and meet degradation requirements.

Related Products

Related News

As sustainable packaging becomes increasingly important, many brands are switching from traditional plastic to eco-friendly alternatives like small compostable bags. […]

BOPP、OPP、PP袋是什么?选择合适包装袋的指南 在包装行业中,BOPP袋、OPP袋 和 PP袋 是最常见的三种塑料包装袋。它们各自具有不同的特点和适用场景,了解它们之间的区别,可以帮助您选择最适合您需求的包装解决方案。本文将为您详细介绍这三种袋子,帮助您更好地选择包装袋。 1. 什么是BOPP袋? BOPP袋(双向拉伸聚丙烯袋)是通过将聚丙烯(PP)薄膜进行双向拉伸处理后形成的袋子。这种工艺使得BOPP袋的强度和透明度更高,表面光滑,适用于需要高度透明、印刷效果好的产品包装。 特点: 高强度:相比其他塑料袋,BOPP袋更加坚固耐用。 优质印刷效果:其光滑的表面非常适合高质量的图文印刷。 防潮:具有一定的防水性能,可以保护包装内容物不受潮湿影响。 应用场景:食品、电子产品、礼品、服装、玩具等高端包装。 2. 什么是OPP袋? OPP袋(定向拉伸聚丙烯袋)是由聚丙烯(PP)材料制成的薄膜经过单向拉伸加工后制成的袋子。OPP袋相对较薄且经济,因此通常用于日常商品包装。 特点: 透明度高:OPP袋呈现出较高的透明性,便于查看袋内物品。 经济实用:OPP袋较为薄弱,适合低成本包装。 适合冷包装:它具有较好的抗寒性和抗紫外线性能。 […]

Flexible packaging has become a top choice for brands looking to balance functionality, cost efficiency, and shelf appeal. Among the […]