Eco-Friendly Frozen Food Packaging Bag for Vegetables & Meat

frozen food packaging bag are produced with durable laminated films for meat, seafood, and vegetables. DSPPACK ffers OEM supply, custom printing, and reliable cold-chain protection.

Key Features & Advantages of Frozen Food Packaging Bags

- Durable Materials– Made from high-strength laminated films to resist tearing and protect frozen goods.

- Moisture & Temperature Resistant – Keeps food fresh and prevents freezer burn during long storage.

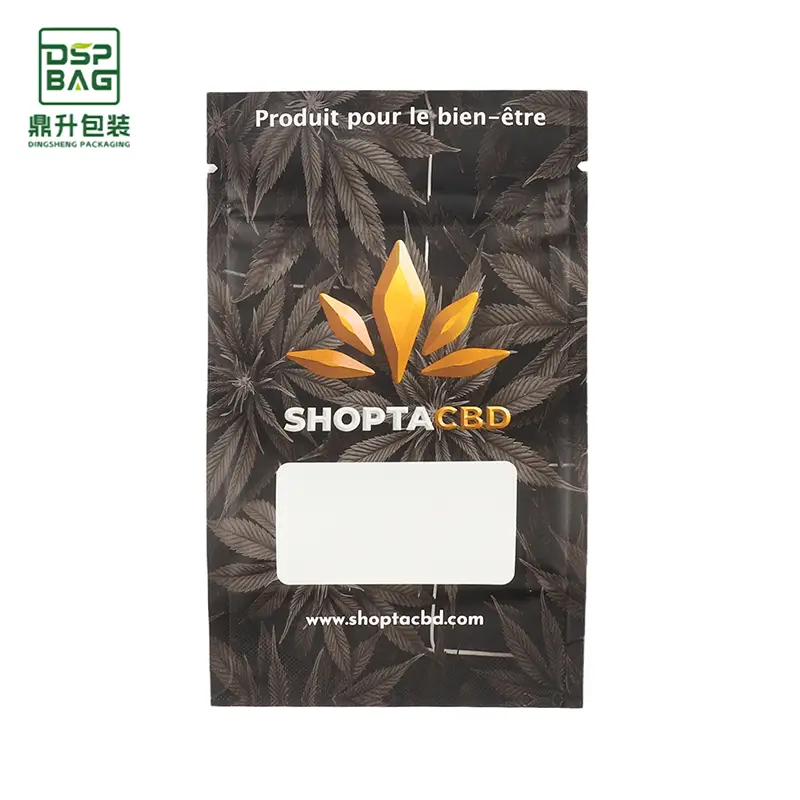

- Custom Printing Options – Supports OEM/ODM with high-quality branding and attractive designs.

- Wide Applications– Ideal for frozen meat, seafood, vegetables, fruits, and ready-to-eat meals.

- Convenient Closures – Available with resealable zippers, tear notches, or vacuum sealing for easy use.

Frozen Food Bag Description

Frozen Food Packaging Bag from our factory is designed with durable laminated films to protect meat, seafood, vegetables, and ready meals from moisture and freezer burn. As a reliable packaging supplier and manufacturer, we provide custom sizes, printing, and wholesale solutions to meet diverse needs. These bags are strong, resealable, and suitable for cold-chain storage, helping distributors and retailers maintain product freshness and extend shelf life. Perfect for bulk buyers, OEM projects, and global export.

Frozen Food Bag/Frozen Food Packaging Bags Data Sheet

| Parameter | Product Specification |

| Product Core Term | Frozen Food Packaging Bag / Frozen Food Pouch |

| Material | Multi-layer laminated films (PET/PE, PET/PA/PE, BOPP/CPP) |

| Thickness | 60-180 microns |

| Structure | Durable, moisture-resistant, freezer safe |

| Size Range | 100g, 250g, 500g, 1kg, 2kg, up to 10kg |

| Shapes | Stand up pouch, flat pouch, gusset pouch |

| Closures | Zipper lock, tear notch, vacuum seal |

| Temperature Range | -40°C to +85°C |

| Barrier Properties | High oxygen & moisture barrier |

| Function | Prevents freezer burn; Extends shelf life |

| Printing Options | Rotogravure up to 10 colors / Digital printing |

| Finishes | Matte, glossy, transparent window |

| Branding | OEM/ODM available for logos, patterns, retail-ready display |

| MOQ | 10,000 pcs (custom orders) |

| Supply Ability | Bulk production with fast lead time |

| Certifications | FDA, EU, ISO, SGS approved |

| Application | Frozen meat, seafood, vegetables, ready-to-eat meals |

| Target Customers | Distributors, retailers, OEM/ODM clients |

Get Free Quote of Frozen Food Packaging Bag

Factory direct, wholesale custom printed frozen food packaging bags

Frozen Food Bag/Frozen Food Packaging Bags Applications

Applications of Frozen Food Bags

Our frozen food bags are ideal for storing and transporting meat, seafood, vegetables, and ready-to-eat meals. Insulated bags for shipping frozen food ensure temperature stability during transit. Bags for frozen food packaging provide moisture protection and prevent freezer burn. Durable frozen food packaging bags are suitable for bulk storage and retail display. Zip lock bags for frozen food offer convenience for portion control and repeated use. Perfect for distributors, retailers, and food service suppliers looking for reliable, high-quality cold-chain packaging solutions.

Frozen Food Packaging Bag FAQ

These bags achieve sustainability primarily through the use of Recyclable Mono-Materials, such as an all-polyethylene ($\text{PE}/\text{PE}$) structure. This single-resin composition allows the entire bag to be recycled where local facilities accept $\text{PE}$ film, diverting waste from landfills compared to non-recyclable multi-material laminates.

The material is engineered with high low-temperature resistance and an excellent Moisture Vapor Transmission Rate ($\text{MVTR}$) barrier. This prevents water sublimation (ice forming) and excessive air exposure, effectively reducing freezer burn and maintaining the texture and flavor of the frozen vegetables and meat.

Yes. The inner layer of the bag is made from food-grade $\text{FDA}$/$\text{EU}$ compliant material that is chemically inert. This ensures no leaching occurs when in contact with varying food compositions, making the bags safe and effective for both fatty meat products and moisture-rich vegetables.

Check product specifications. Many eco-friendly frozen food bags are designed for cold storage only. However, some specialized versions utilize high-temperature-tolerant $\text{PE}$ or $\text{PP}$ structures that are safe for “boil-in-bag” or microwave use. Always confirm the temperature tolerance on the specific product label.

Frozen food bags typically use a very strong heat seal for the initial closure to ensure air-tightness. They often include a resealable zipper closure inside the bag, allowing the consumer to securely close the bag after pouring out a portion, maintaining freshness for the remaining contents.