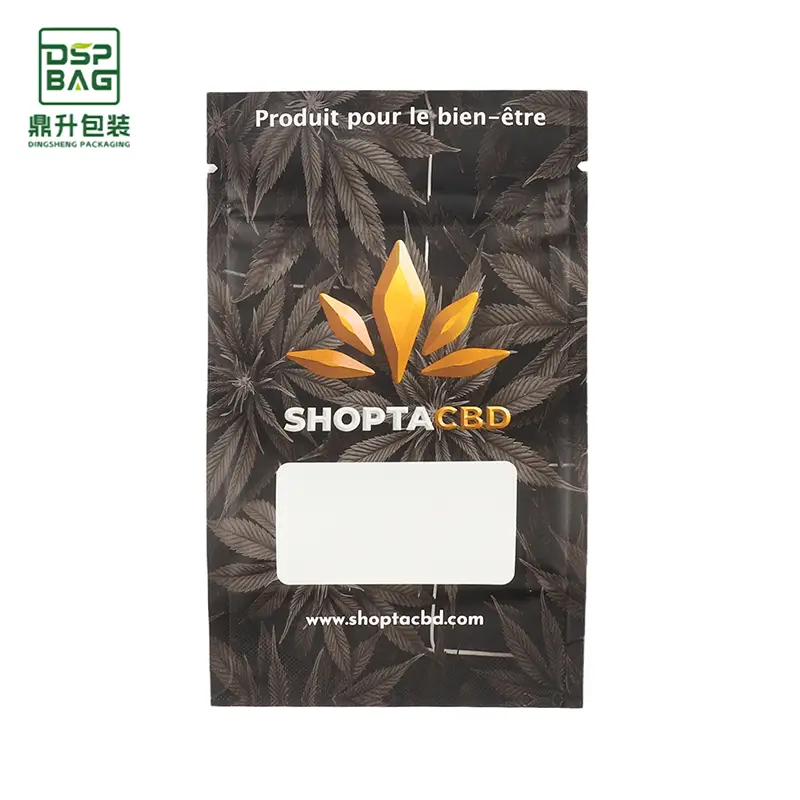

Custom Die-Cut Design Special-Shaped Bag for Retail Packaging

Special-shaped bags are made with durable plastic for food and cosmetics. Professional suppliers deliver custom packaging solutions.

Product Features & Advantages of Special-Shaped Bags

- Unique Design Flexibility– Custom shapes enhance product differentiation and brand visibility.

- High-Quality Materials – Durable, eco-friendly options provide strong protection for contents.

- Versatile Applications – Widely used in food, cosmetics, electronics, and industrial packaging.

- Excellent Barrier Properties– Moisture-proof and odor-resistant, keeping products fresh and safe.

- Custom Branding Support– Available with printing, logo, and special finishes for marketing impact.

Special-Shaped Bags Description

Special-Shaped Bags are innovative packaging solutions supplied by our company, designed with customized dimensions, unique outlines, and durable materials. As a professional manufacturer and exporter, we provide wholesale biodegradable and eco-friendly options that enhance product visibility and meet diverse industry needs such as food, cosmetics, and electronics. These special-shaped bags not only protect contents with reliable barrier performance but also help distributors and traders create stronger branding impact and attract customers in bulk markets.

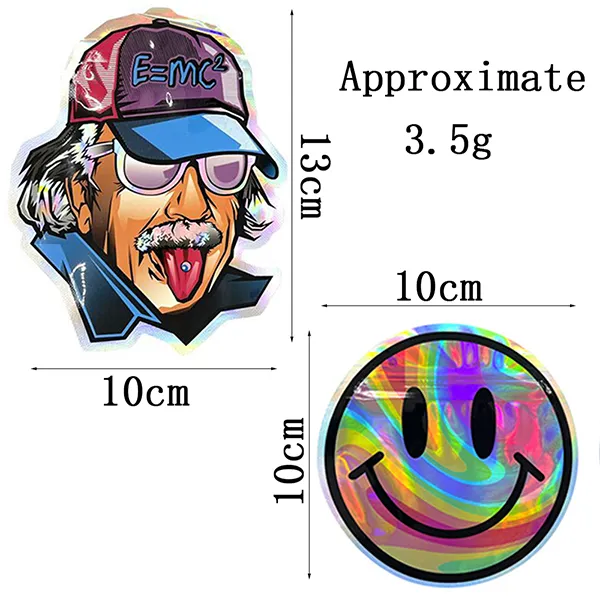

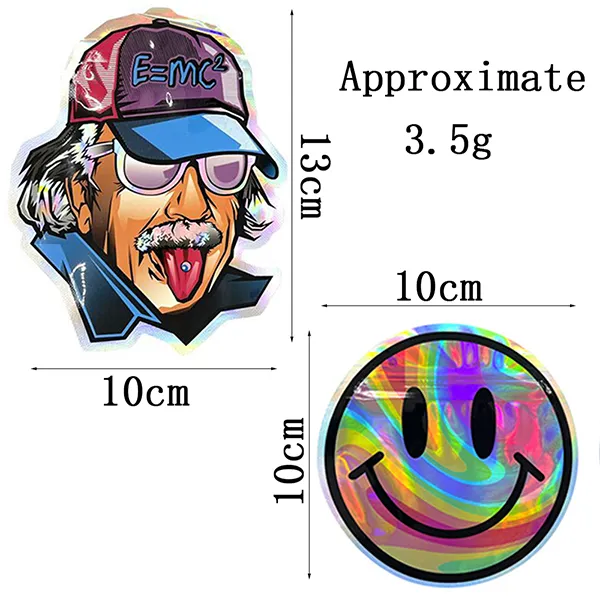

Special-shaped-bag / Unique Packaging Bags Data Sheet

| Item | Specification / Description |

| Product Name | Special-Shaped Bag |

| Material Options | PET/AL/PE, PET/PE, BOPP/CPP, Biodegradable film |

| Thickness Range | 50-200 microns (customizable) |

| Size Options | Customized dimensions and shapes |

| Shape Feature | Irregular, die-cut, customized outline |

| Printing | Gravure printing up to 10 colors |

| Surface Finish | Glossy, matte, transparent, or mixed |

| Barrier Properties | Moisture-proof, oxygen barrier, light-blocking |

| Closure Options | Zipper, heat seal, spout, resealable |

| Application Fields | Food packaging, cosmetics, pet food, electronics, promotional items |

| Eco-Friendly Options | Biodegradable & compostable film available |

| MOQ | 10,000 pcs (negotiable) |

| Supply Type | Manufacturer, Wholesale, OEM/ODM |

| Export Markets | North America, Europe, Asia-Pacific, Middle East |

| Certification | ISO, FDA, SGS, Compostable certification (on request) |

Get Free Quote of special-shaped-bag

Factory direct, wholesale custom printed shaped bags

Special-shaped-bag / Unique Packaging Bags Applications

Special-Shaped Bag Applications

- Special-shaped bags are designed to combine functionality with eye-catching design, making them ideal for brands seeking differentiation.

- Food & Beverage Industry: Irregular shape bags enhance product visibility for snacks, candies, or beverages, attracting customer attention.

- Cosmetics & Personal Care: Unique packaging bags are perfect for masks, lotions, and beauty samples, emphasizing luxury and brand identity.

- Electronics & Accessories: Custom printed shaped bags provide distinctive packaging for gadgets, cables, and small electronics.

- Pet Products: Irregular shape bags and custom printed shaped bags make treats and supplements more appealing on shelves.

- Promotional & Gift Packaging: Unique packaging bags serve as premium carriers for marketing events, seasonal gifts, or giveaways.

FAQ

The biggest advantage is visual impact and brand differentiation. Special-shaped bags (like product silhouettes, animal shapes, or asymmetrical designs) immediately capture consumer attention and stand out. It turns the packaging into an extension of the product, greatly enhancing the brand’s storytelling and premium appeal.

Design constraints primarily focus on sealing and structural integrity. While the shape can be flexible, the heat seal area must be sufficiently flat and continuous to ensure the package is airtight and leak-proof. The design must also ensure the bag maintains its structural stability after the product has been filled.

Generally, yes. Due to the requirement for creating custom die-cut tooling and setting up precise cutting machinery, the initial startup costs and the $\text{MOQ}$ are higher than for standard pouch shapes. $\text{MOQ}$ depends on the size and complexity but is usually geared toward high-volume or premium retail products to offset the tooling cost.